Our company and Team

Miller Weldmaster

Standard & Custom Hot Air, Hot Wedge, & Impulse Welding Machines - fully automated systems and material handling solutions.

Popularity

24

Showing 1-20 of 20 products

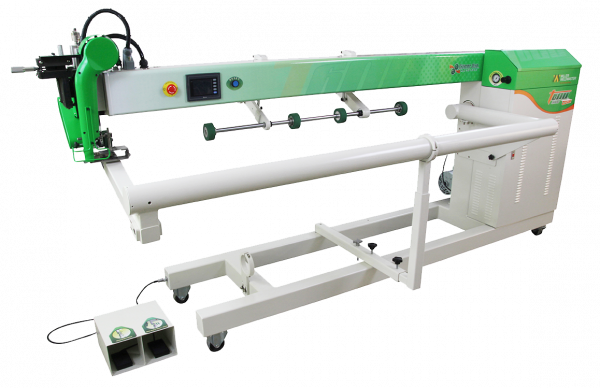

T600 Extreme Shade

Miller Weldmaster UK T600 Extreme Shade Hot Wedge Welding machine. A COMPLETE SHADE AND AWNING SOLUTION

Effortless operating welder for welding PVC or acrylic shades, awnings and structures with additional fabric handling support. Its heavy duty construction allows for the toughest jobs.

RFlex Press

Miller Weldmaster RFlex Press 4KW stationary Radio Frequency (RF / High Frequency (HF) welder - small, multipurpose foot/pneumatic press HF welder with switchable: work table and gooseneck support

RFlex Travel

Miller Weldmaster RFlex Travel 17KW stationary Radio Frequency (RF / High Frequency (HF) welder - travelling model for industrial products such as tarpaulins, tents, lorry tarps, high speed doors and more.

RFlex

Miller Weldmaster RFlex 17KW stationary Radio Frequency (RF / High Frequency (HF) welder for industrial products

T300 NEW 2022

Hot air and / or hot wedge welder, produces airtight and waterproof seams for 2D and 3D inflatables, shaped products and tubes, sheets, banners and much more.

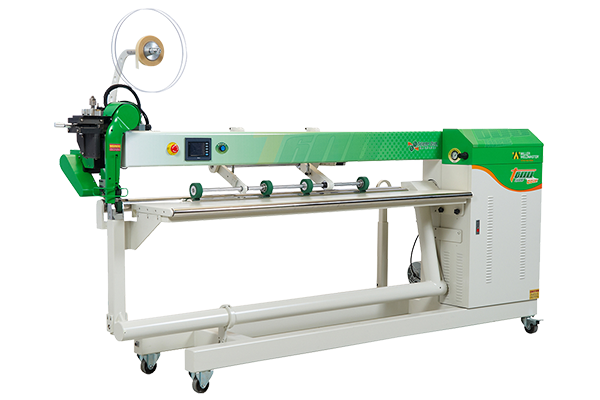

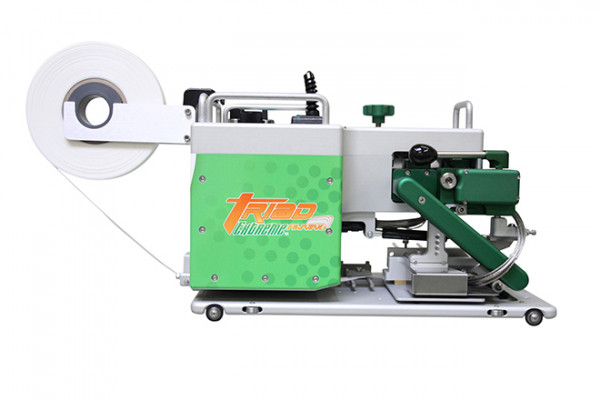

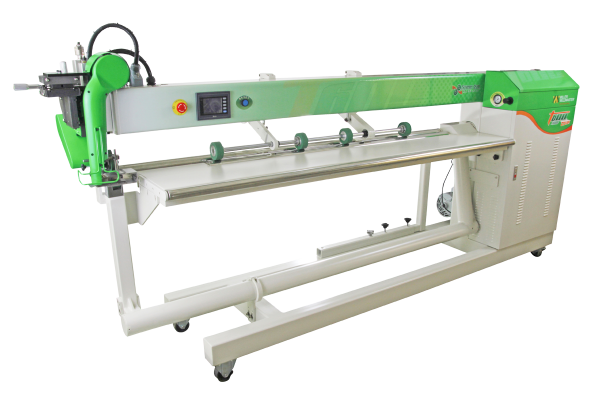

Triad Extreme Universal

Travelling or stationary hot wedge welder for varied production needs - customisable

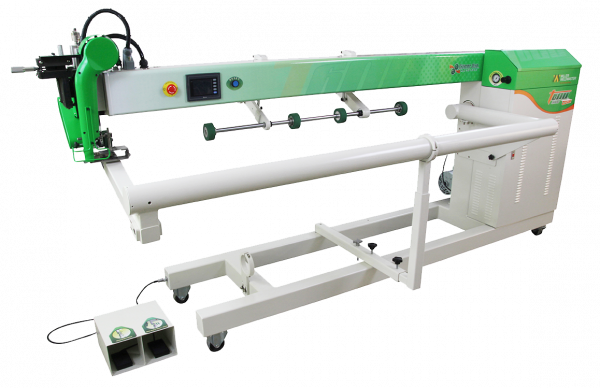

Triad Extreme Shelter

Travelling or stationary hot wedge welder for shelters / structures, tarps, covers, tents.

Triad Extreme Cover

Travelling or stationary hot wedge welder for tarps, covers, liners, geomembranes, lorry curtains.

Triad Extreme Awning

Travelling or stationary hot wedge welder for awnings, shades / tension structures.

T600 Extreme Shelter

Miller Weldmaster UK T600 Extreme Shelter Hot Wedge. Make Any Size, Tent or Shelter

Heavy duty construction for your largest shelter production needs. Weld large panels and finish edges on one machine. The T600 Extreme Shelter is ready for any tent or shelter application.

112 Extreme

Travelling head welder for long, straight seams - fast and very accurate

T600 Extreme Flex

Miller Weldmaster UK T600 Extreme Flex Hot Air and Hot Wedge Welding machine. The T600 Extreme Flex welds hems, hems with pocket and hems with rope. We're known for the longest-lasting machines. The T600 Extreme Flex is built for multiple-shift production, and with its solid-steel design, this machine will last for multiple decades.

T600 Extreme Curve

Miller Weldmaster UK T600 Extreme Curve WATERPROOF SEAM WELDER FOR INFLATABLES

This machine produces airtight and waterproof seams for 2D and 3D, meeting the toughest demands with additional fabric handling support. Packed with everything needed to weld curves and unique shapes for the production of inflatables, tanks, bladders and more.

T600 Extreme Cover

Miller Weldmaster UK T600 Extreme Cover Hot Wedge Welding machine. A TARP AND COVER PRODUCING WORK HORSE

Miller Weldmaster's T600 Extreme Cover will weld your panels and finish the edges of your covers and tarps. The T600 Extreme Cover will meet any production demand.

T300 Extreme Shade

Hot wedge welder for PVC or acrylic shades, awnings, marine, and structures

T300 Extreme Flex

Hot air and / or hot wedge heat systems for versatility to make a variety of products.

T300 Extreme Edge

Fastest, hot wedge welder for sign and banner products

T300 Extreme Curve

Hot air welder, produces airtight and waterproof seams for 2D and 3D inflatables, shaped products and tubes.

T3 Extreme

Desktop hot wedge welder for signs and banners - for small business

Eliteair

Miller Weldmaster UK - Eliteair Hot Air Welding machine. High-Powered Hot Air Hand Tool for all Industrial Fabrics

The ELITEAIR is a versatile handheld welding tool for in-house or in-the-field instant repairs of industrial fabrics.