Our company and Team

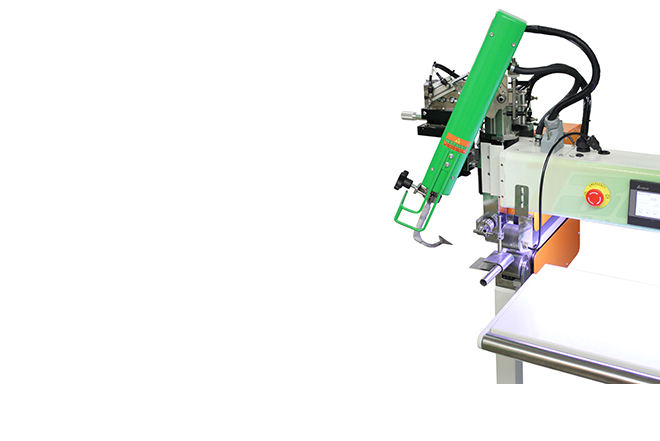

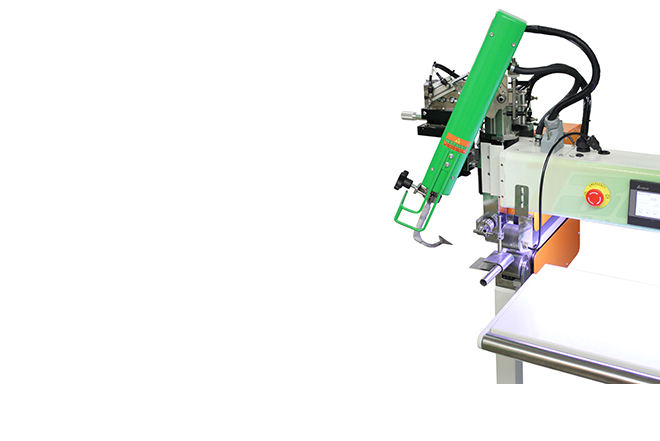

T300 Extreme Curve

How to make an Inflatable product

Welding Inflatable Boats

Hot Air & Hot Wedge Seam welding machine | Inflatable products

Welding Drop Stitch Products using Hot Air Technology

Hot Air Welding Tube Ring

T300 Extreme Curve

Airtight and Waterproof Seams for the Toughest Applications

Miller Weldmaster's T300 Extreme Curve produces airtight and waterproof seams for 2D and 3D inflatables. Discover how the T300 Extreme Curve hot-air and hot-wedge welding machine can help you create seams for uniquely shaped inflatables.

Best For:

- Aerospace

- Athletic Mats

- Flexible Storage Tank/Bladders

- Paddle Boards

- Pools

- Inflatables

- Outdoor Furniture

Features & Benefits

- Quick-setting recall with touch screen and recipe storage of 25 memory settings

- Increased product efficiency with dual arms to configure straight and curved seams

- Quick, repeatable, precision- head adjustments

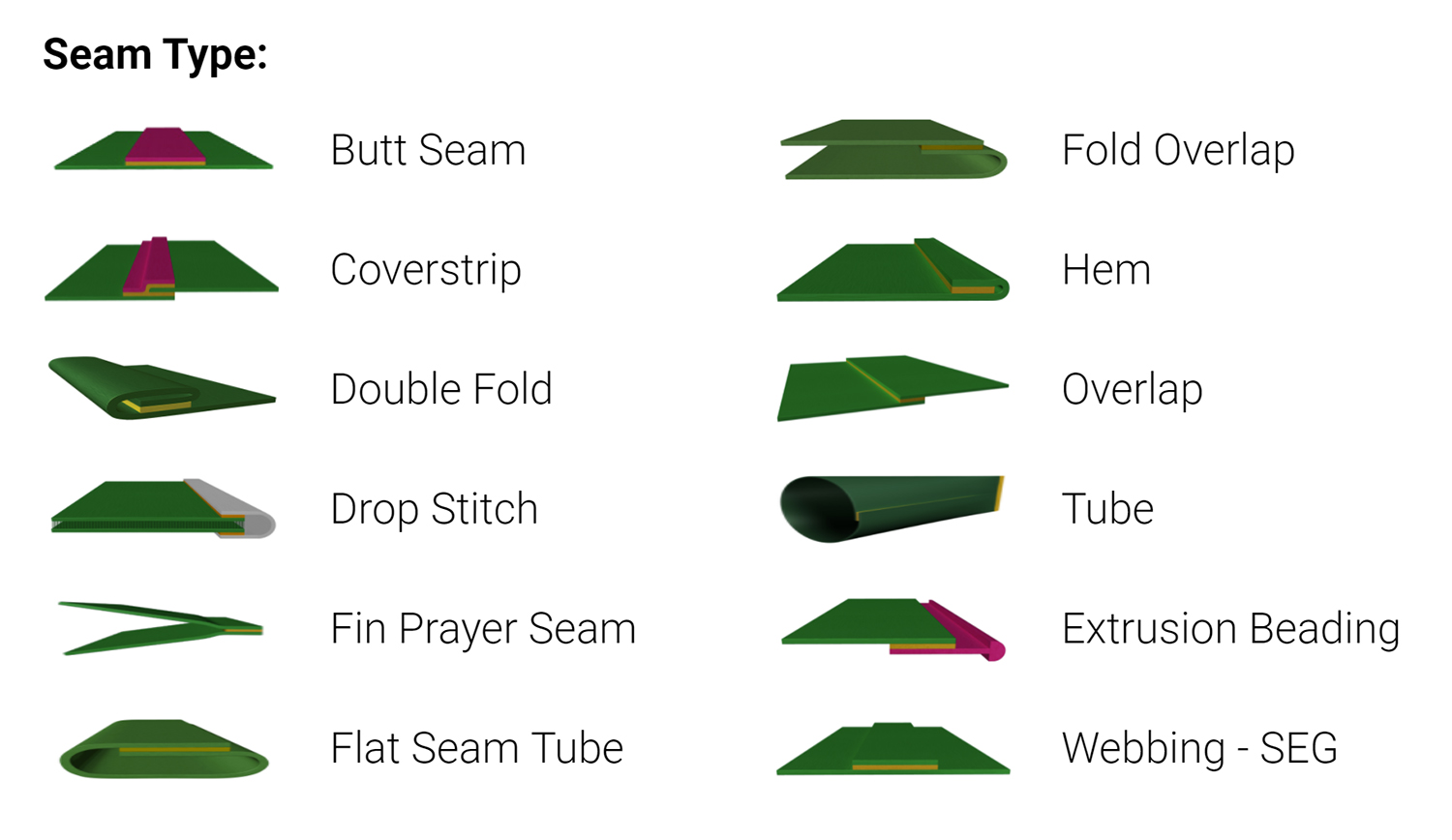

- Quick, easy guide change for multiple seam configurations

- Can be customized to fit your exact specifications

Power Requirements

- 208-240 Volts - Single Phase -25 Amp.

- 380-400 Volts - Single Phase -16 Amp.

Air Requirements

- 5cfm @ 100psi

Power Consumption

- Approx. 6kW

Maximum Temperature

- Hot Air: 730˚C (1,346˚F)

- Hot Wedge: 450˚C (842˚F)

Throat Width

- 0.88m (34.5")

Dimensions

- Width: 0.6m (23")

- Length: 1.5m (59")

- Height: 1.5m (59")

Weight

- 231kg (510lb)

Seam Width

- 10 to 50mm (0.5 - 2”)**

Welding Cycle

- Up to 30m/min (100ft/min)*

* Depending on the application, the seam width and the type of material used

** Additional guides might be necessary

brochures

pre-install info

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.