Our company and Team

T300 Extreme Flex

PVC, Vinyl, Acrylic Fabric Welding & more

T300 Continuous Hot Air Welder

How to make an Inflatable Product

The Fastest Way To Finish Banners & Signs

How to weld Zipper on T300

T300 Extreme Flex

Most Versatile Welder

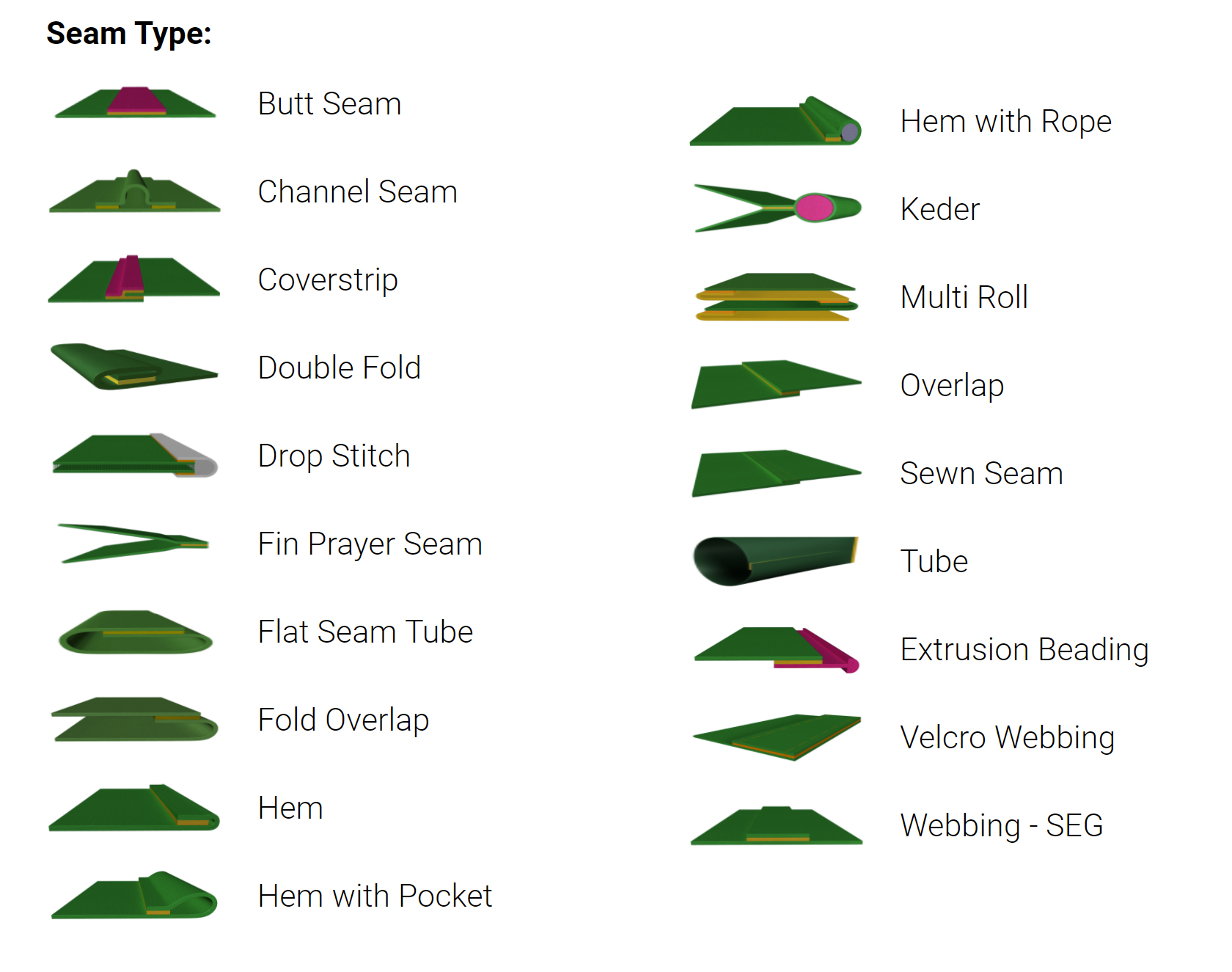

the T300 Extreme Flex uses hot air and hot wedge technologies with an array of seam types. Discover how the T300 Extreme Flex can help you finish tents, shelters, tarps, covers and more in no time.

Best For:

- Aerospace

- Athletic Mats

- Banners

- Containment Booms

- Conveyor Belts

- Cured In Place Pipeline

- Curtains - Agriculture

- Curtains - Truck Side

- Roller Doors

- Evacuation Slides

- Filtration

- Mattresses

- Pool Covers

- Pools

- Roofing Membranes

- Screens

- Shelters Structures

- Sifting Screens

- Signs

- Tarpaulins/Covers

- Tents

- Tubes

Features & Benefits

- Quick setting recall with easy operation touch screen and recipe storage

- Increased product versatility with dual arms to configure straight or curved seams

- Quick, repeatable head adjustments for precision welding

- Available in hot air, hot wedge or both for product versatility

- Multiple seam configurations for quick, easy guide change

- Can be customized to fit your exact specifications

Power Requirements

- 208-240 Volts - Single Phase -25 Amp.

- 380-400 Volts - Single Phase -16 Amp.

Air Requirements

- 5cfm @ 100psi

Power Consumption

- Approx. 6kW

Maximum Temperature

- Hot Air: 730˚C (1,346˚F)

- Hot Wedge: 450˚C (842˚F)

Throat Width

- 0.88m (34.5")

Dimensions

- Width: 0.6m (23")

- Length: 1.5m (59")

- Height: 1.5m (59")

Weight

- 231kg (510lb)

Seam Width

- 10 to 50mm (0.5 - 2”)**

Welding Cycle

- Up to 30m/min (100ft/min)*

* Depending on the application, the seam width and the type of material used

** Additional guides might be necessary

brochures

pre-install info

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.