T300 Extreme Shade

How to Make Custom Striped Awnings - T300 Extreme Shade I Miller Weldmaster

Hot Wedge Welding Machine for Custom Stripe Awnings, Shades & more | T-300 Extreme

Acrylic Welding Set Up - T300 Extreme I Miller Weldmaster

Hot Air and Wedge Welding Machine and Conveyor for Awnings, Shades & More | T-300 Extreme

Versatile Heat Seaming Machine for Awnings, Banners, Inflatables and more

T300 Extreme Shade

A Complete Shade, Awning, And Marine Sealer Solution

Miller Weldmaster's T300 Extreme Shade is a simple operating welder for PVC or acrylic shades, awnings, marine, and structures. Using hot wedge technology, this welder's straightforward design and controls mean consistent and easy product construction.

Best For:

- Aerospace

- Awnings

- Blinds

- Roller Doors

- Marine

- Shades/Tension Structure

- Tarpaulins/Covers

Features & Benefits

- Quick setting recall with easy operation touch screen and recipe storage

- Increased product versatility with dual arms to configure straight seams

- Quick, repeatable head adjustments for precision welding

- Available in hot air, hot wedge or both for product versatility

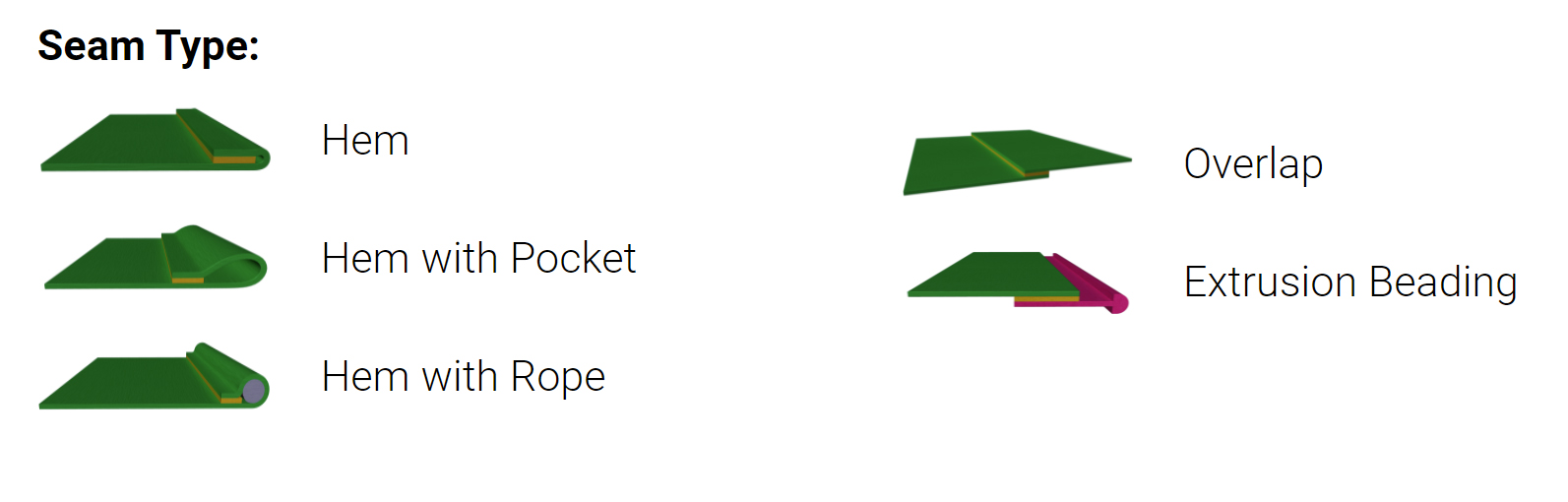

- Multiple seam configurations for quick, easy guide change

Power Requirements

- 208-240 Volts - Single Phase -25 Amp.

- 380-400 Volts - Single Phase -16 Amp.

Air Requirements

- 5cfm @ 100psi

Power Consumption

- Approx. 6kW

Maximum Temperature

- Hot Air: 730˚C (1,346˚F)

- Hot Wedge: 450˚C (842˚F)

Throat Width

- 0.88m (34.5")

Dimensions

- Width: 0.6m (23")

- Length: 1.5m (59")

- Height: 1.5m (59")

Weight

- 231kg (510lb)

Seam Width

- 10 to 50mm (0.5 - 2”)**

Welding Cycle

- Up to 30m/min (100ft/min)*

* Depending on the application, the seam width and the type of material used

** Additional guides might be necessary

brochures

pre-install info

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.