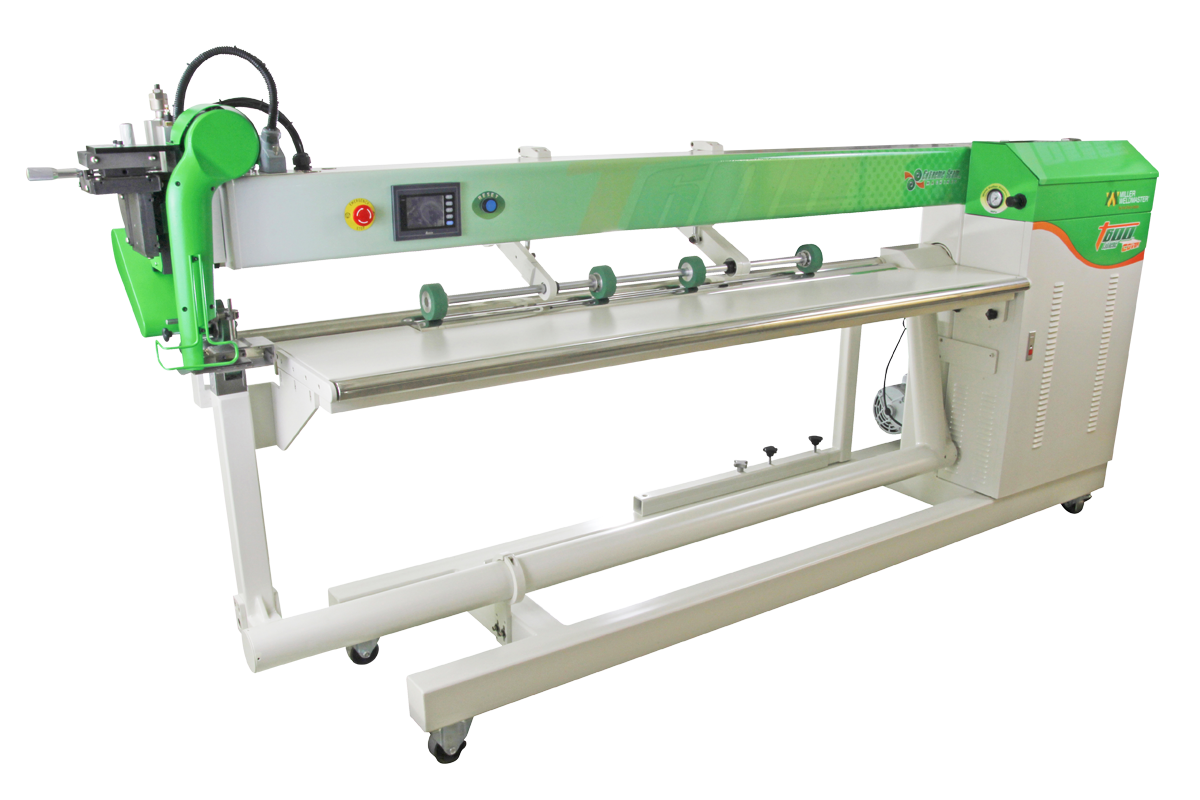

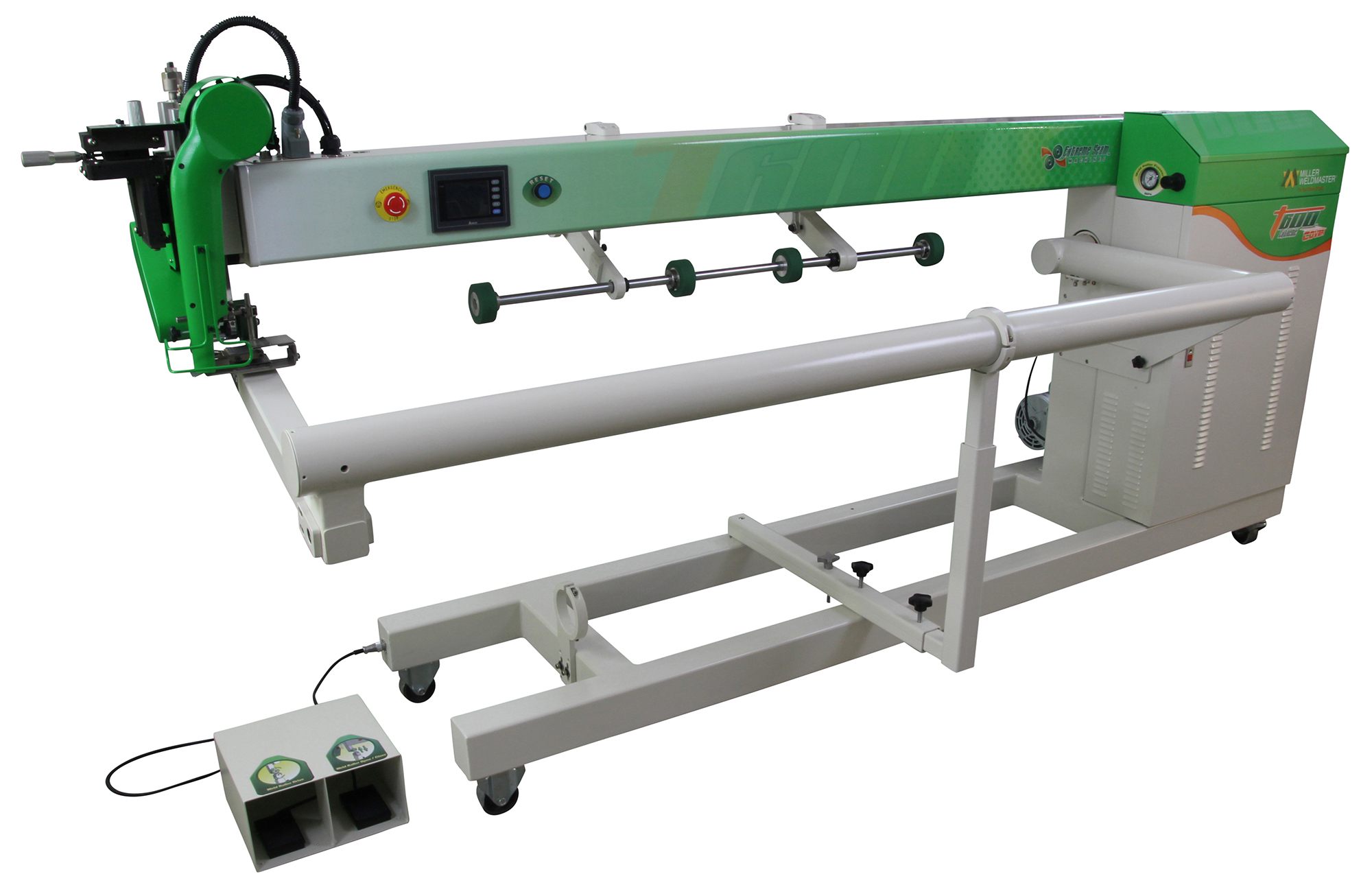

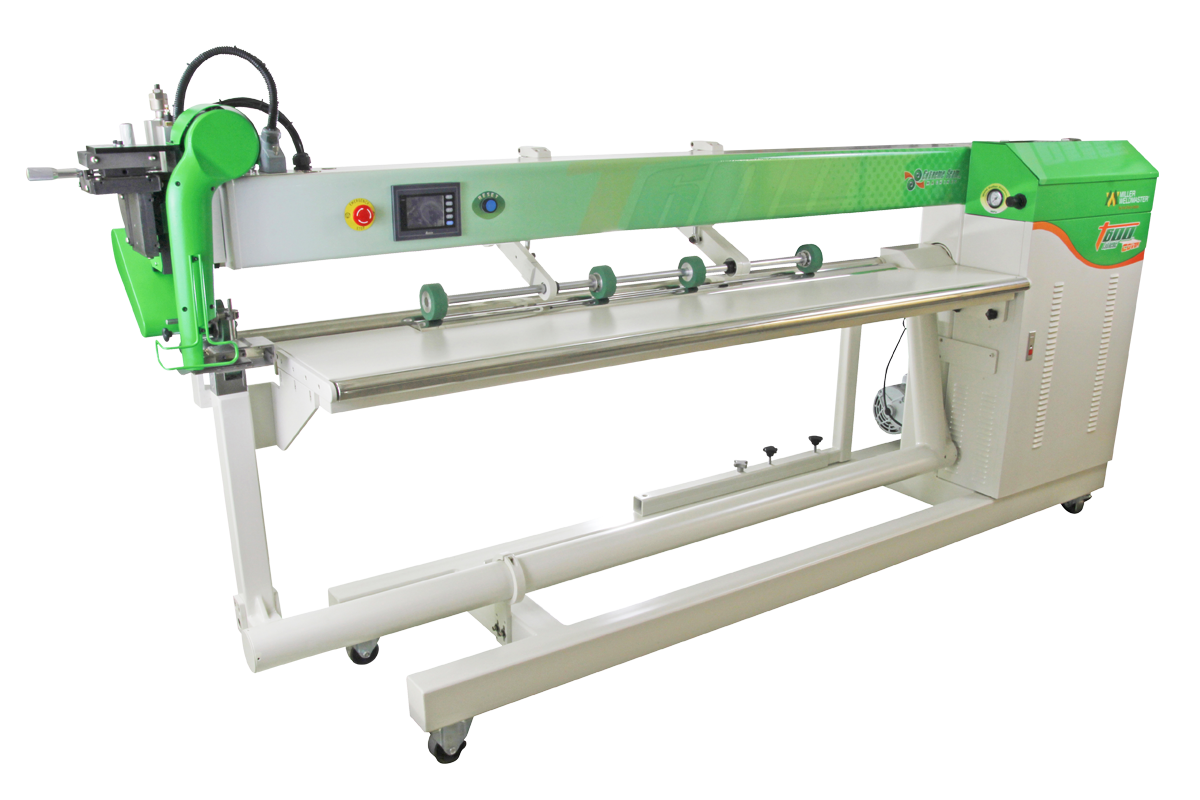

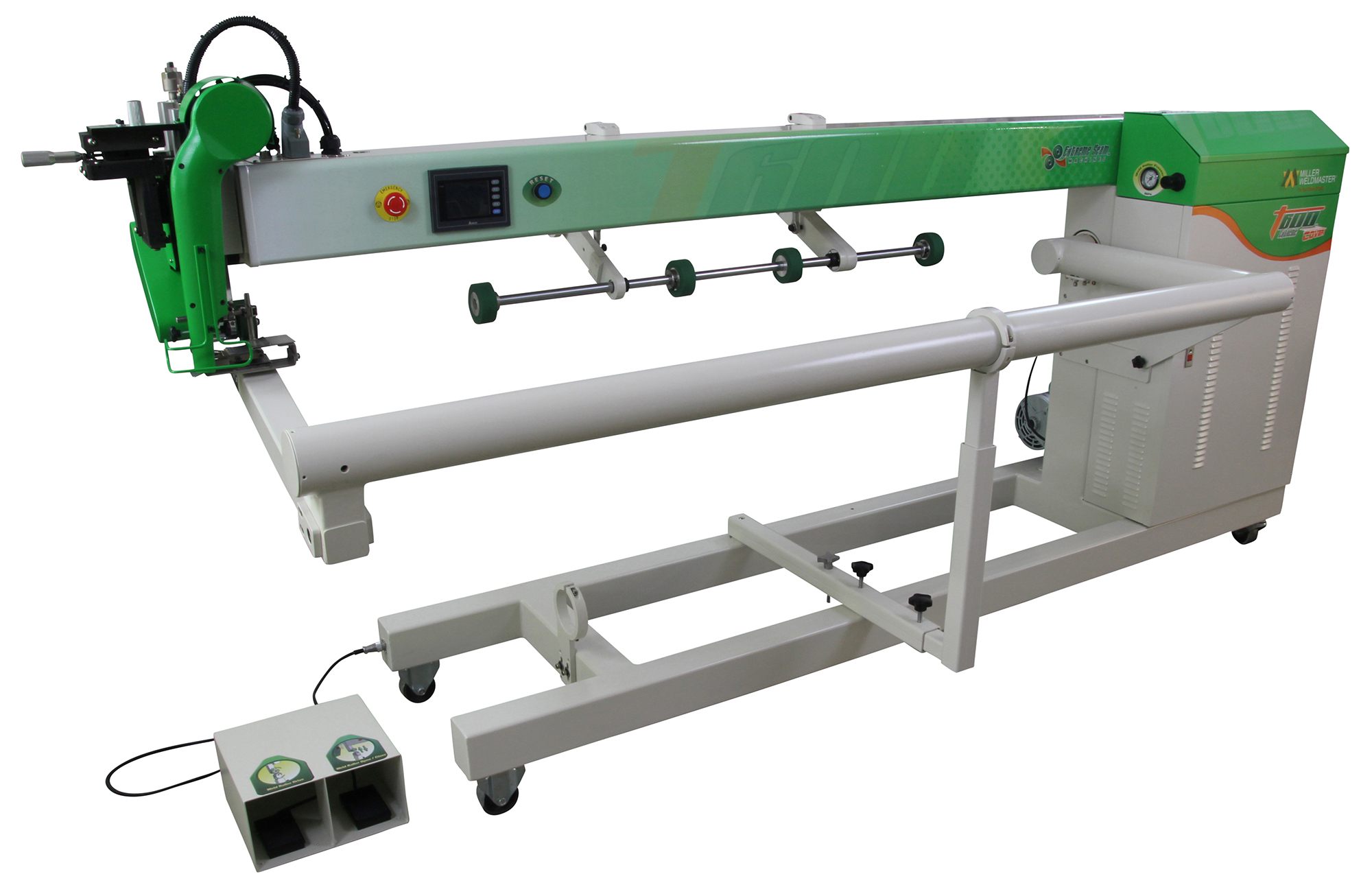

T600 Extreme Flex

Weld Your Shelters, Tents, Canopies & More

Welding Reinforced Ducting or Tubes

High Production of PVC Products

Welding Waterproof Curved Seams

Weld An Overlap With A Coverstrip

T600 Extreme Flex

Our Most Versatile Welder

The T600 Extreme Flex offers the use of hot air or hot wedge welding technologies with an array of seam types and extended fabric handling support. You''ll get consistent, easy product construction with efficient and straightforward design and controls. Contact Us. The dual heat system of the T600 Extreme allows complete product flexibility. Two seams can be completed simultaneously to save time and labor.

The T600 Extreme Flex welds hems, hems with pocket and hems with rope. We're known for the longest-lasting machines. The T600 Extreme Flex is built for multiple-shift production, and with its solid-steel design, this machine will last for multiple decades.

Best For:

- Aerospace

- Athletic Mats

- Containment Booms

- Curtains - Agriculture

- Curtains - Truck Side

- Roller Doors

- Evacuation Slides

- Mattresses

- Pool Covers

- Pools

- Inflatables

- Shelters Structures

- Tarpaulins/Covers

- Tents

Features & Benefits

- Quick- setting recall with touch screen and recipe storage for multiple material types

- Increased product versatility with dual arms

- Easily weld wider fabrics with extended throat length

- Easier fabric handling with inboard and outboard fabric puller

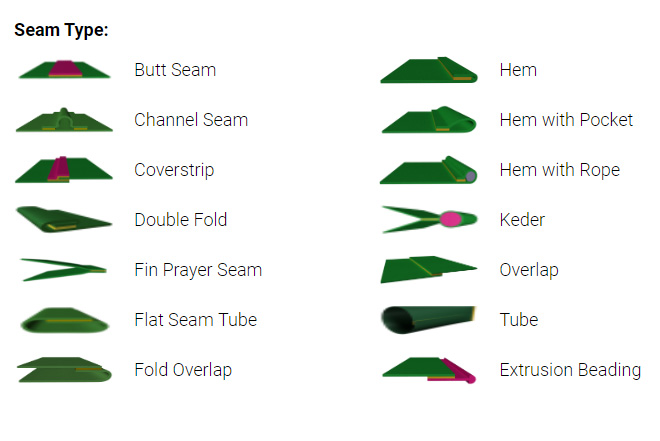

- Multiple seam configurations available with quick and easy guide changes to make a variety of products

- Available in hot air, hot wedge or both for product versatility

Base Machine Includes:

- Hot Air or Hot Wedge Heat System

- Hem Guide

- Overlap Guide

- 25 Recipe Storage Settings

- Training & Installation

Optional Add On's:

- Webbing Guide & Dispenser

- Additional Weld Guides

- Additional Weld Widths Available

Power Requirements

- 208 - 240 Volts - Single Phase - 25 Amp.

- 380 - 400 Volts - Single Phase -15 Amp.

Air Requirements

- 2cfm @ 100psi

Power Consumption

- Approx. 6kW

Maximum Temperature

- Hot Air: 730˚C (1,346˚F)

- Hot Wedge: 450˚C (842˚F)

Throat Width

- 2.03m (79.9")

Dimensions

- Width: 0.6m (23")

- Length: 3m (120")

- Height: 1.5m (59")

Weight

- 680kg (1,500lb)

Seam Width

- 10 - 50mm (0.5 - 2”)**

Welding Cycle

- Up to 30m/min (100ft/min)*

* Depending on the application, the seam width and the type of material used

** Additional guides might be necessary

BROCHURES

PRE-INSTALL INFO

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.