Our company and Team

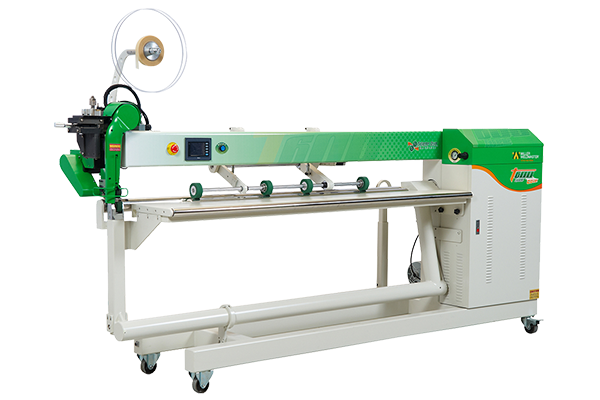

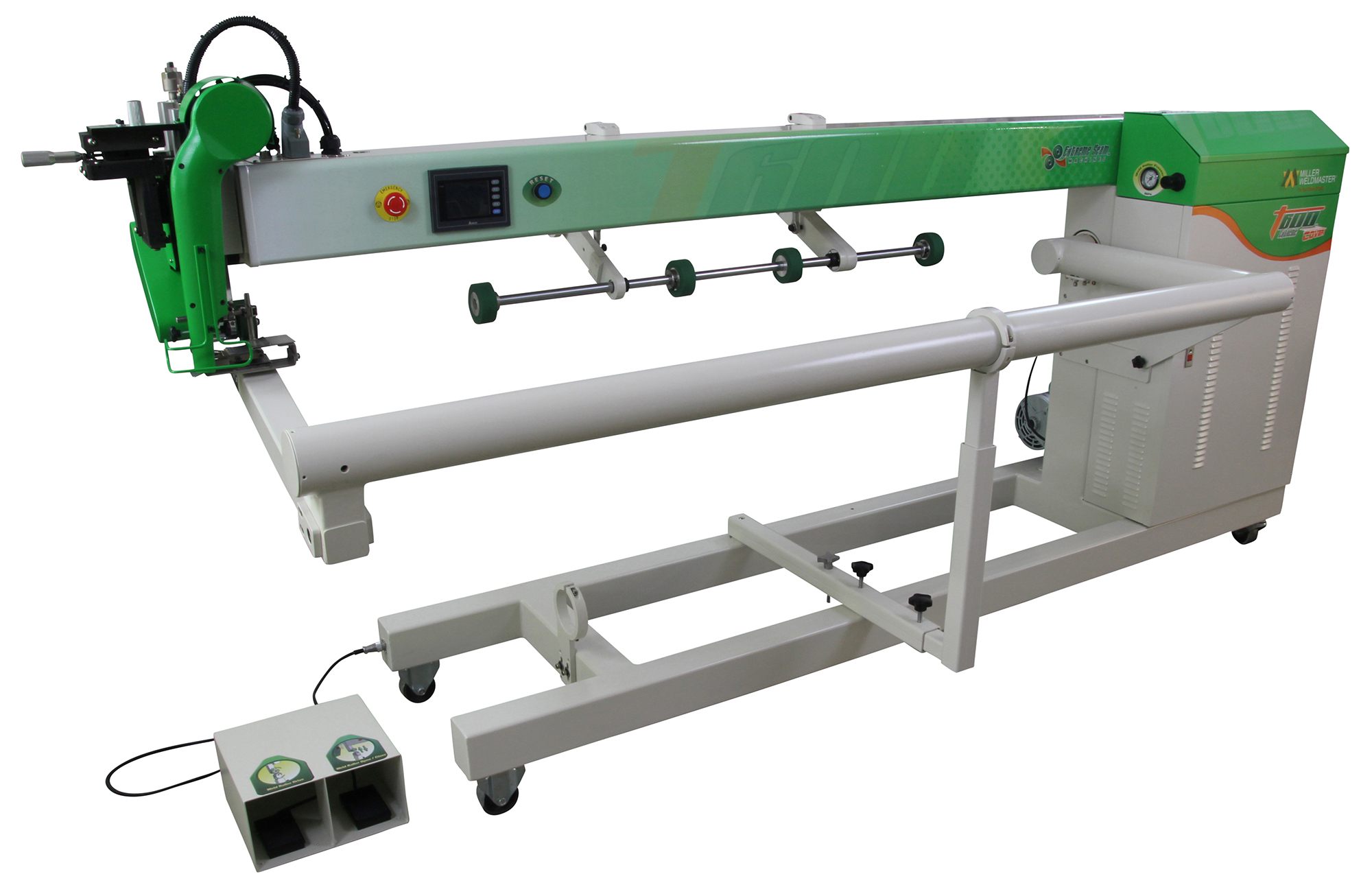

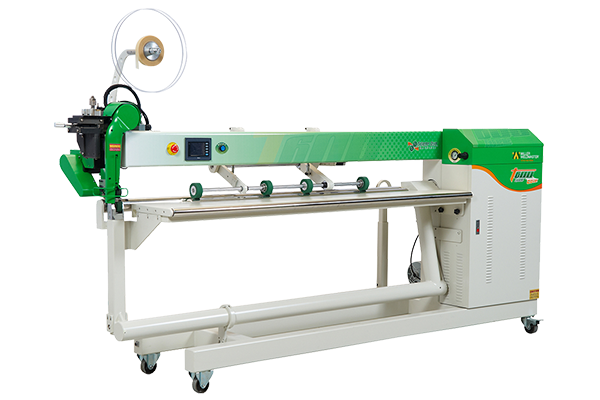

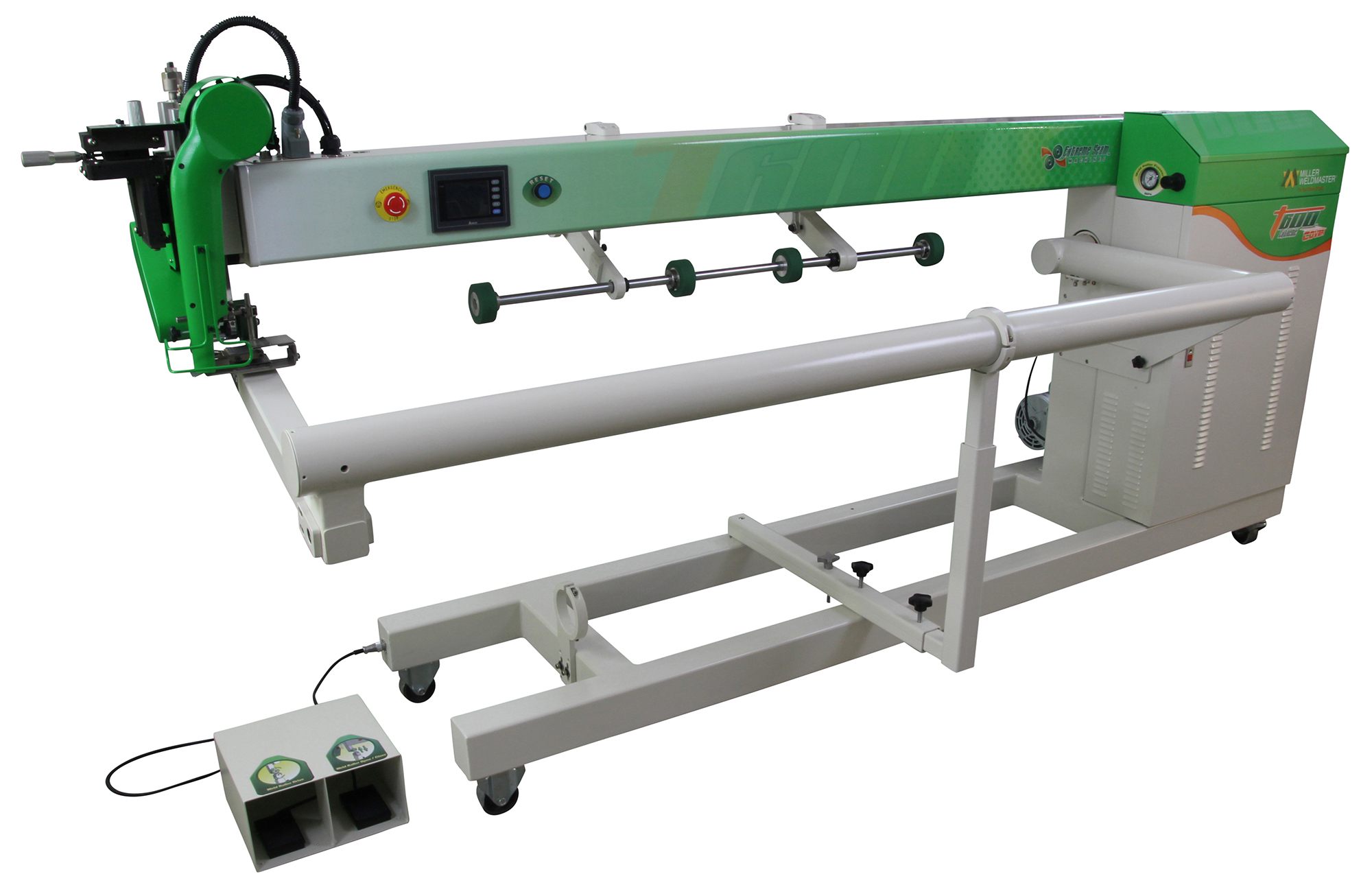

T600 Extreme Shade

Versatile Large & Heavy Production Demands for PVC & More

Hot Air Wedge Fabric Welding Machine | PVC, Awnings & Canopy

How to Make Custom Striped Awnings - T600 Extreme Shade I Miller Weldmaster

Hot Air, Wedge PVC Welding Machine | Shelters, Tents, Canopies

Acrylic Welding Set Up - T300 Extreme I Miller Weldmaster

T600 Extreme Shade

A Complete Shade and Awning Solution

Effortless operating welder for welding PVC or acrylic shades, awnings and structures with additional fabric handling support. Its heavy duty construction allows for the toughest jobs.

Best For:

- Aerospace

- Awnings

- Blinds

- Roller Doors

- Marine

- Shades/Tension Structure

- Tarpaulins/Covers

Features & Benefits

- Easy operation touch screen with recipe storage for quick setting recall

- Equipped with dual arms for increased product versatility

- Inboard and outboard fabric puller for easier fabric handling

- Quick, repeatable head adjustments for precision welding

- Available in hot wedge, hot air or equipped with both for optimal product production

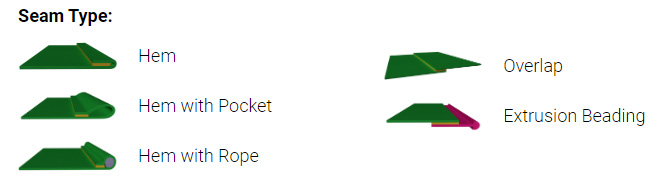

- Quick, easy guide change for multiple seam configurations

Power Requirements

- 208 - 240 Volts - Single Phase - 25 Amp.

- 380 - 400 Volts - Single Phase -15 Amp.

Air Requirements

- 2cfm @ 100psi

Power Consumption

- Approx. 6kW

Maximum Temperature

- Hot Air: 730˚C (1,346˚F)

- Hot Wedge: 450˚C (842˚F)

Throat Width

- 2.03m (79.9")

Dimensions

- Width: 0.6m (23")

- Length: 3m (120")

- Height: 1.5m (59")

Weight

- 680kg (1,500lb)

Seam Width

- 10 - 50mm (0.5 - 2”)**

Welding Cycle

- Up to 30m/min (100ft/min)*

* Depending on the application, the seam width and the type of material used

** Additional guides might be necessary

BROCHURES

PRE-INSTALL INFO

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.