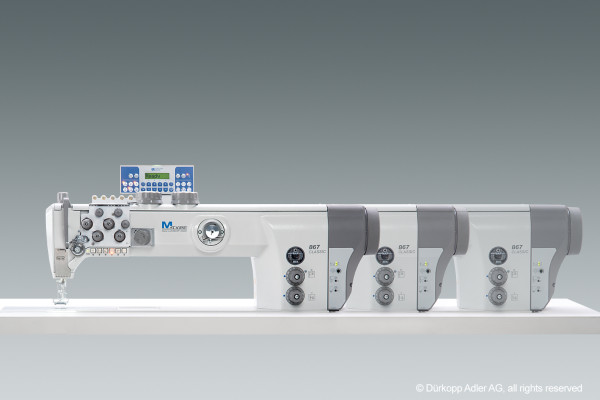

867

867

The 867 M-TYPE offers a wide variety of solutions and enables an optimal customization to your need - with the following features and options:

- Walking feet and needle feed (combined feed)

- For medium / heavy applications

- 1 and 2 needle models available in all versions

- Built-in LED light (standard with Goldline models) *

- Variety of different presser feet *

- Edge guides *

- Thread monitoring equipment *

- Direct Drive motor (-M models only)

- XXL, 70% more bobbin capacity (depends on model)

- Stitch count function (depends on model / motor) *

* Option

ECO

Basic model

Due to outstanding performance parameters the subclasses of the program level M-TYPE ECO lockstitch flat bed machines with triple feed offer high functionality and flexibility – at an attractive price.

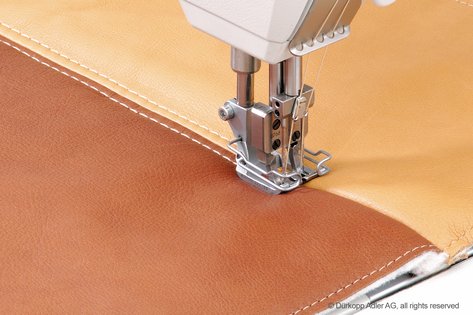

The powerful and effective triple feed system guarantees a trouble-free and displacement-free material feed when processing most different fabric thicknesses and structures.

The DAC eco control is equipped with convenient basic functions such as needle positioning, soft start and realization of a pedal-operated single stitch.

The subclasses of the M-TYPE ECO program level are suitable as robust operating equipment for universal sewing operations in the field of home upholstery, room decoration, leather goods as well as on technical textiles.

Classic Silverline

The Silverline equipment variant are equipped with automatic basic functions like: thread trimmer, automatic backtacking, automatic sewing foot lift.

The highly efficient sewing parameters combined with automatic basic functions make the 867 CLASSIC Silverline an ideal operating means for the universal use in the field of medium-heavy duty applications.

The powerful and effective triple feed system guarantees a trouble-free and displacement-free material feed when processing most different fabric thicknesses and structures.

Classic goldline

Maximum Productivity and Efficiency

The M-TYPE flatbed machines with electro-pneumatic full equipment and triple feed are equipped with all M-TYPE-typical performance features and advantages.

In addition to the automatic basic functions such as thread trimmer, automatic backtacking and automatic sewing foot lift, the subclasses of the 867 CLASSIC Goldline convince with further additional functions for higher productivity and increased sewing comfort.

The additional integrated second thread tension, integrated second stitch length and quick stroke adjustment allow to produce with the highest quality in a particularly flexible and efficient way even for changing and difficult sewing applications. Furthermore, the full equipment of the M-TYPE is complemented by additional comfort functions: The optimum illumination of the sewing area and the maintenance indicator ensure the best possible design of the sewing workstation.

The powerful and effective feeding system with bottom feed, needle feed and alternating top feet guarantees a trouble-free and displacement-free material feed when processing most different fabric thicknesses and structures. The highly efficient sewing parameters combined with a great variety of equipment make the 867 CLASSIC Goldline an ideal operating means for the universal use in the field of medium-heavy duty applications.

Brochures

Parts lists

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.