Our company and Team

Triad Extreme Cover

Portable Hot Wedge Welder designed for Tarp and Cover Applications | Triad Extreme

Portable Efficient Welder for PVC, Acrylic & More | Triad Extreme

Triad Extreme Cover

Small Portable Welder for your Cover and Tarp Production

Comes fully assembled and ready to weld stationary or traveling on table top track. The Triad Extreme Cover is ready to meet any cover or tarp production demands.

Best For:

- Curtains - Truck Side

- Geomembranes/Liners

- Tarpaulins/Covers

Features & Benefits

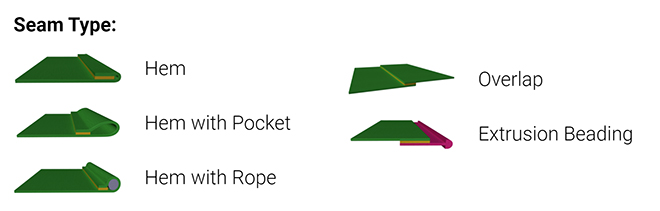

- Multiple seam configurations available for multiple finishing demands

- Excellent visibility of the welding area

- Swing out wedge provides for easy cleaning

- Stationary or automatic travel on track for hands free operation

- Available in either 110V or 230V to suite your facility requirements

Power Requirements

- 120 Volts - Single Phase - 5 Amp.

- 230 Volts - Single Phase - 2.65 Amp.

Power Consumption

- Approx. 0.6kW

Maximum Temperature

- 525˚C (977˚F)

Dimensions

- Width: 0.254m (1o")

- Length: 0.508m (20")

- Height: 0.305m (12")

Weight

- 23kg (50lb)

Seam Width

- 10-50mm (0.5-2")

Welding Cycle

- Approx. 10m/min.*

* Depending on the application, the seam width and the type of material used

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.