RFlex

Most Versatile Radio Frequency Welding Machine

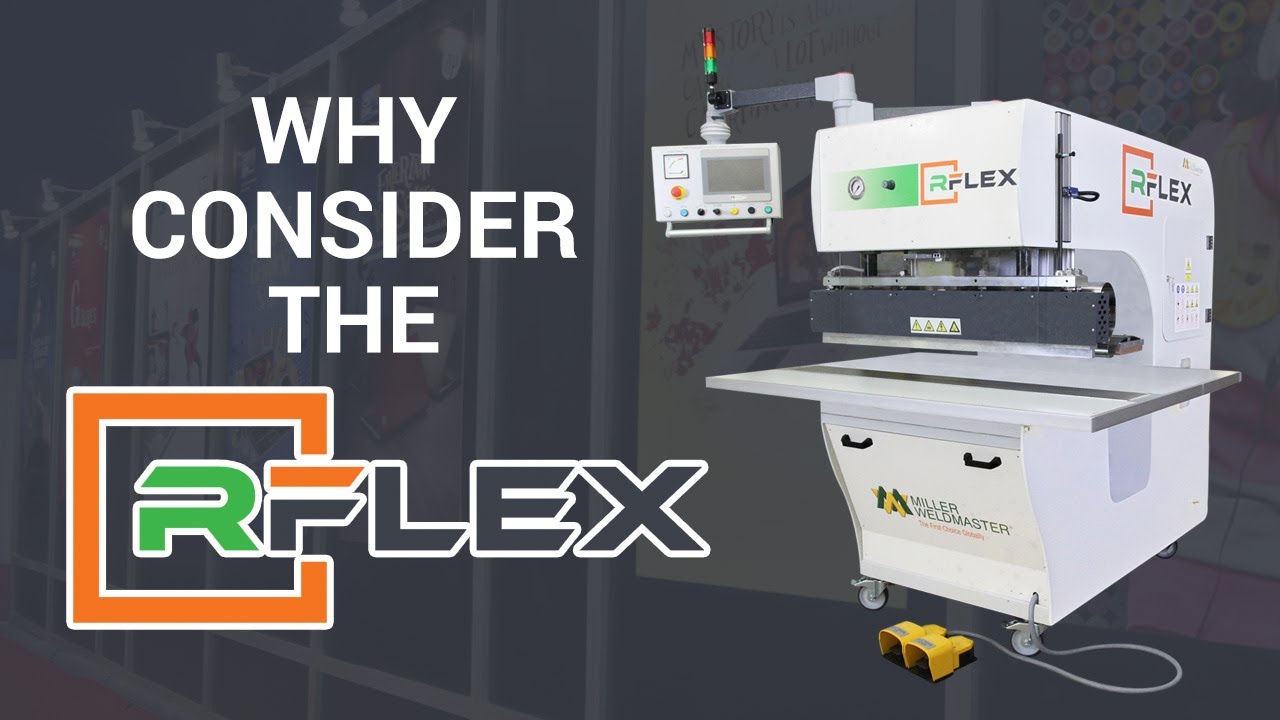

RFLEX - The Most Versatile Radio Frequency Welding Machine (RF/HF)

RFLEX FREEWELD

How Does RF Welder Work? - RFlex I Miller Weldmaster

Radio Frequency Sign & Billboard Welding Machine!

RFlex

The Most Versatile Radio Frequency Machine

The RFlex stationary welder is the industry’s most versatile radio frequency welder available on the market. Radio Frequency (RF) is also known as High Frequency (HF) welding.

RFlex was designed for the production of tarpaulins, tents, truck tarps, high speed doors, and any other flexible Polyvinyl chloride (PVC) or Polyurethane (PU) product. With enhanced features such as, a foldable trough for better material handling, a joystick to accurately line up your material every time, autotuning for consistent welds, your production will be even more efficient and reliable.

BEST FOR:

- Aerospace

- Athletic Mats

- Awnings

- Billboards

- Blinds

- Clear Span Buildings

- Containment Booms

- Conveyor Belts

- Curtains - Agriculture

- Curtains - Gymnasium

- Curtains - Truck Side

- Roller Doors

- Evacuation Slides

- Flexible Storage Tank/Bladders

- Greenhouses

- Mattresses

- Pergolas

- Pool Covers

- Pools

- Inflatables

- Screens

- Shades/Tension Structure

- Shelters Structures

- Signs

- Tarpaulins/Covers

- Tents

Features & Benefits

- Universal usage for PVC, PU, TPU, reinforced technical textiles

- Foldable large worktable with deep trough creating ample space behind the electrode for easy material handling

- New generation stable and efficient RF power generator

- Easily change dies with QuickGRIP release system of the electrodes

- Easier material placement and better visualization of weld with built in LED illumination.

- Positioning laser guides

- Manual, semi-automatic and automatic operation

- 10" color touch screen HMI panel on a swing arm for use on any side of the machine

- SafeDOWN anti-crush electrode safety motion system

- Fully automated weld cycles with 1000 weld cycle recipe memory

- Auto-tuning for steady RF power feed to assure consistent welds

- Fully programmable PLC with memory settings

- RF emission protection.

- Custom dies available for versatile production

- Line up your material accurately every time with the joystick and foot pedal precision

- Easy to use intuitive operating menu with machine specific software

- Ultrafast monitoring of arcs and overloads for protecting the integrity of the electrodes and the welded material

- For welding non-RF weldable fabrics, the RFlex can be fitted with an impulse electrode

FREEWeld

- FREEWeld is an optional solution that allows for grounding emissions without lowering a grounding foot.

- The FREEweld option eliminates the grounding foot needing to be perfectly flat on the table. This enables the operator to make a wider range of products.

- Creates a stronger, more aesthetic, weld with two parallel weld lines.

Power Requirements

- 400/415 Volts - Three Phase - C40 Amp.

Air Requirements

- minimum 90 psi

Power Consumption

- Approx. 25kW

Dimensions

- Width - 1,700mm

- Length - 1,970mm

- Height - 2,400mm

Weight

- 1,100kg (2,425lb)

Electron Tube

- Air Cooled Metal-Ceramic Triode

Antiflash System

- ZTG Antiflash ™ Ultra Fast Solid State Arc protection

AUTOTUNING System

- ZTG ATS ™ System for precice HF power control

HF Weld cycle control

- ZTG WCS ™ Weld Check System verifying HF weld process

Control System

- PLC & 10" Touch Screen HMI with memory storage

Electrode Length

- 1,200mm (optional 1,500mm)

- Additional sizes available

Electrode Stroke

- 160mm

Space Behind Electrode

- 840mm + deep back trough and folding table

Work Table Dimensions

- 1,600 x 800mm

Trough Size

- 400 x 500mm

Electrode Mount

- QuickGRIP ™ , fast pneumatic clamp

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.