RFlex Press

Miller Weldmaster RFlex Press welder

How Does RF Welder Work? - RFlex I Miller Weldmaster

RFlex Press

The Most Compact Universal RF Welder

The RFlex Press welder is the smallest machine in the Radio Frequency line. Small but mighty, the RFlex Press brings the power of larger RF machines with a small footprint. Designed for the production of small intricate applications including automotive, medical equipment, and packaging accessories or products. The RFlex Press can weld PVC, PET, PU , TPO, or PLA. With enhanced features such as precision line, spot, curve weld technology, autotuning for consistent welds, and a durable work table that will make your production more efficient and reliable. Or, add on the gooseneck work area to help with material handling and flexibility in your movement.

Best For:

- Aerospace

- Inflatable Boats

- Packaging

- Inflatables

- Shades/Tension Structure

- Shelters Structures

- Tarpaulins/Covers

- Tents

- Automotive

- Embossing

- Medical

- Protective Gear

- Prototype Work

Features & Benefits

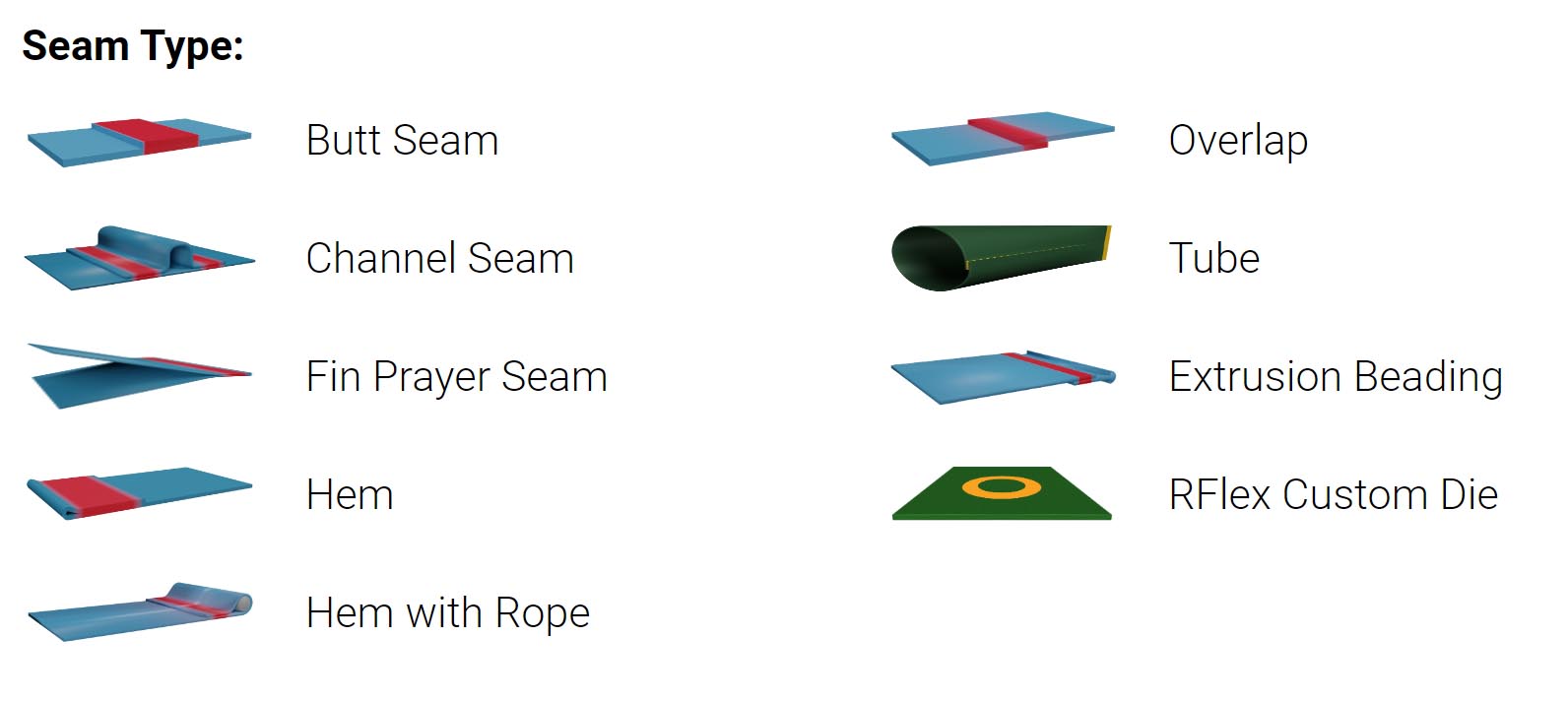

- Multiple Welding Shapes and Custom 2D and 3D Dies

- Universal usage for PVC, PU, TPU, reinforced technical textiles

- New generation stable and efficient RF power generator with Autotune Capabilities

- Easier material placement and better visualization of weld with built-in LED illumination.

- Pneumatic Foot Operation for precise material and weld placement

- StrokeDOWN System with a crank-knob system for easy setup of height adjustment of welding electrode from the work table

- Semi-automated weld cycles with 100 weld cycle recipe memory

- Easy to use Fully programmable PLC with memory settings and touch screen

- RF emission protection.

- Custom dies available for versatile production

- Easy-to-use intuitive operating menu with machine-specific software

- Ultrafast monitoring of arcs and overloads for protecting the integrity of the electrodes and the welded material

Optional Add-On:

- Gooseneck Work Area

Power Requirements

- 400 Volts - Three Phase

Power Consumption

- Approx. 6kW

Dimensions

- Width - .72m (28")

- Length - 1.3m (51")

- Height - 1.75m (69")

Weight

- 300kg (661lb)

Electron Tube

- Air Cooled Metal-Ceramic Triode

Antiflash System

- ZTG AntiFlash™ Ultra Fast Solid State Arc Limiter

AUTOTUNING System

- ZTG ATS™ System for precise HF power control

Control System

- PLC & 7" Touch Screen HMI with memory

Electrode HOLDING PLATEN

- 190 x 90 mm (adjustable in 3 planes)

Electrode Stroke

- 0.15m (6")

Space Behind Electrode

- 0.32m (12.6")

Work Table Dimensions

- 0.8m x 0.48m (31.5" x 19")

PNEUMATIC CYLINDER PRESSURE

- 450kg

brochures

- RFlex Press spec sheet

- RFlex Press Footprint

pre-install info

- RFlex Press pre-installation requirements

Related products

Subscribe for the latest offers, product and trade show news

Keep up to date with news and be the first to hear about new products, offers and exhibitions.